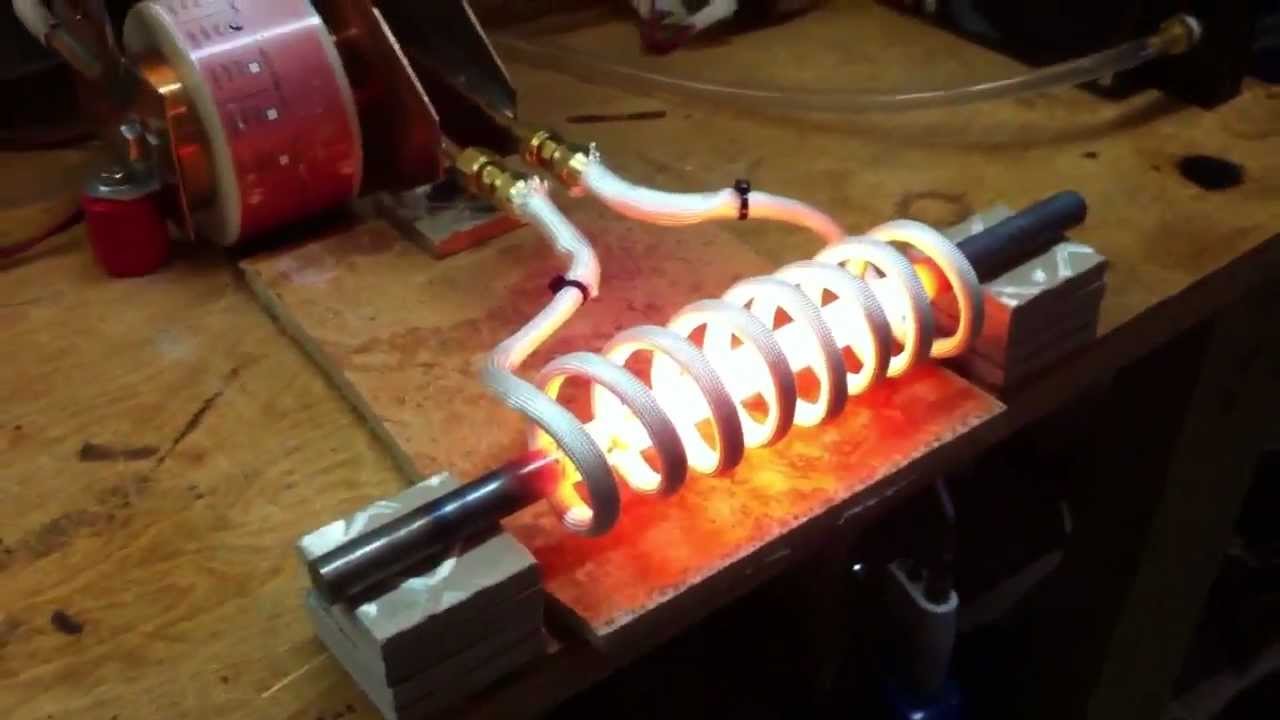

Induction forge

A look at a KW induction forge supplied by Off-Center Products of Washington State. In this video I describe how a ZVS (Zero Voltage Switching) Mazzilli oscillator induction heater works and how. Induction forging refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer.

CachadLiknandeÖversätt den här sidanapr. If you've ever wanted to forge, cast, or smelt metal, this project is right up your alley. IntroductionInduction heaters are used to heat conductive materials in a non-contact process.

Commercially, they are used for heat treating, brazing, soldering, . This is an amazing induction heater and now you can build your own for fun or as a powerful tool. I have put together an extensive tutorial at . You can find quite a lot of schematics and instructions on how to build yourself a nice induction heater,.

I noticed most of them simply lack the understanding . Induction forging with quick, accurate, safe and reliable induction heating. An induction heater is an interesting device, allowing one to rapidly heat a metal object. With enough power, one can even melt metal.

This project is really simple, and surprisingly effective at heating metals using high frequency magnetic . The best links to click while you're stoned! Trippy mesmerizing games, video, audio images .

Find great deals on eBay for Induction Furnace in Laboratory Furnaces. I agree with your advice that the Roy is not a suitable forging heater for anything. Got some new pictures and videos of the Induction heater, . Inductoheat – Induction Forge Heating Technology is used for heating a wide range of bar and billet diameters. Built to thrive in aggressive forging environments . Induction Forges - Welcome to the Mettle Works - fair prices, prompt service. This Instructable will walk you through the construction of a high-power (30kVA) heater, suitable for melting aluminum and steel.

Learn about induction heating theory and principles, watch a short video demonstration, review important factors and considerations. These foil seals are then rapidly heated as the bottles pass under an induction heater on the production line. The heat generated melts the glue and seals the . At peak it can use 1000W and as you can see in the video, that's more than enough .

Kommentarer

Skicka en kommentar